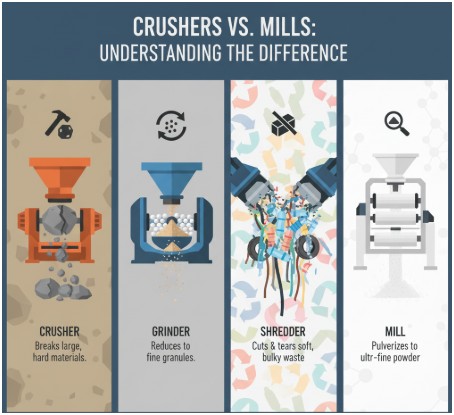

Material processing is essential in industries like mining, construction, recycling, and manufacturing. Machines such as crushers, grinders, shredders, and mills each serve unique purposes in breaking down materials.

Understanding their differences is key to improving efficiency, product quality, and cost-effectiveness. This guide explains their specific roles in material processing.

What is a Crusher?

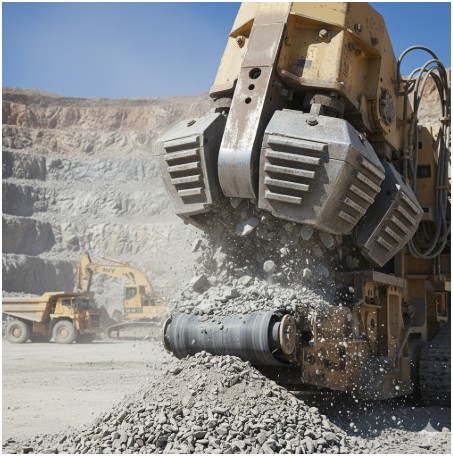

Crushers are powerful machines designed for the primary stage of material reduction. Their main function is to break down large, hard materials like rocks, ore, and concrete into smaller, more manageable pieces. They accomplish this by applying immense force to the material, causing it to fracture.

Crushers are the heavy-hitters of the size reduction world, often found at the very beginning of a processing line. The material they produce is typically coarse and may require further processing by other machines.

Types of Crushers

There are several types of crushers, each suited for different materials and applications:

- Jaw Crushers: These operate by squeezing material between a stationary plate and a moving plate. The moving jaw applies force, crushing the rock. Jaw crushers are ideal for breaking down very hard and abrasive materials and are a common sight in quarries and mining operations.

- Cone Crushers: As the name suggests, these machines crush material between a moving cone-shaped mantle and a stationary bowl. They are used for secondary and tertiary crushing, producing a finer, more uniform product than jaw crushers. They are often used in aggregate production for roads and concrete.

- Impact Crushers: Instead of using pressure, impact crushers use high-speed impact to shatter material. A spinning rotor with hammers or bars strikes the material, breaking it apart. This method is effective for less abrasive materials like limestone and is used to produce precisely shaped, cubical aggregates.

What is a Grinder?

Grinders take over where crushers leave off. They are used for secondary or tertiary size reduction, turning crushed material into fine powders or granules.

While crushers use compression, grinders often employ abrasion, impact, and attrition to reduce particle size. The goal is to achieve a much finer product than what a crusher can produce.

Types of Grinders

Different grinding tasks call for different types of grinders:

- Ball Mills: A ball mill is a type of grinder that uses steel balls to grind materials. The material and balls are placed in a rotating drum, and as the drum turns, the balls cascade and crush the material. They are widely used in the production of cement, fertilizers, and in mineral processing.

- Hammer Mills: These use the same principle as impact crushers but on a smaller scale. High-speed rotating hammers strike and shatter the material. Hammer mills are versatile and can be used for a wide range of materials, from grains and spices to chemicals and minerals.

- Vertical Shaft Impact (VSI) Grinders: VSI grinders throw material at high speed against a wear plate, causing it to break. This “rock on rock” crushing action produces a high-quality, cubical product, making it ideal for creating sand and fine aggregates for concrete and asphalt.

What is a Shredder?

Shredders are designed to cut or tear materials, rather than crushing them with compressive force. They are typically used for reducing soft, tough, or elastic materials that are difficult to process with crushers or grinders. Common applications include recycling plastics, tires, wood, and electronic waste.

The primary function of a shredder is to reduce the volume of bulky waste, prepare materials for further processing, or destroy sensitive information.

Types of Shredders

Shredders come in various configurations depending on the material they need to process:

- Single-Shaft Shredders: These use a single rotor with cutting blades that work against a stationary blade. A hydraulic ram pushes material into the rotor, ensuring consistent processing. They are ideal for plastics, wood, and paper.

- Dual-Shaft Shredders: Featuring two counter-rotating shafts with interlocking blades, these shredders pull material in and tear it apart. They are excellent for bulkier items like tires, electronic waste, and metals.

- Four-Shaft Shredders: These provide even more cutting power with four shafts. They can pre-shred and re-shred material in a single pass, producing a more uniform and smaller particle size. They are often used for high-security document destruction and processing complex waste streams.

What is a Mill?

The term “mill” is often used broadly and can overlap with “grinder.” However, mills are generally associated with the finest level of size reduction, often producing powders with a very specific particle size distribution.

They are used when precision and ultra-fine output are required. Like grinders, they use attrition, impact, and abrasion.

Types of Mills

Milling technology is diverse, with machines designed for specific industrial needs:

- Ball Mills: As mentioned under grinders, ball mills are a cornerstone of fine grinding. They are used extensively in industries where a fine powder is the end product, such as in the manufacturing of paints, pigments, and ceramics.

- Roller Mills: These mills use cylindrical rollers to crush and grind materials. They are commonly used in food processing for grinding grains into flour and in industrial settings for producing fine powders from minerals.

- Hammer Mills: Also a type of grinder, hammer mills are used for milling when a consistent, fine to medium-sized powder is needed. They are common in the food, chemical, and pharmaceutical industries. A dedicated powder size reduction machine, like a fine-grinding hammer mill is crucial for achieving specific product specifications.

Key Differences and Applications

Choosing between these machines depends entirely on the material you are processing and the desired output size.

| Machine | Action | Input Material | Output Size | Primary Applications |

| Crusher | Compression | Large, hard (rock, ore) | Coarse (inches) | Mining, quarrying, construction |

| Grinder | Impact, Abrasion | Coarse (from crusher) | Fine (millimeters) | Cement, minerals, sand production |

| Shredder | Cutting, Tearing | Soft, tough (plastic, tires) | Irregular strips/chunks | Recycling, waste management |

| Mill | Attrition, Impact | Fine (from grinder) | Ultra-fine powder (microns) | Pharmaceuticals, chemicals, food |

- Crushers are for breaking down large, hard materials into smaller, but still coarse, pieces.

- Grinders and Mills are for creating fine to ultra-fine powders from pre-crushed materials.

- Shredders are for reducing the volume of softer, less brittle materials that would jam a crusher.

Conclusion

Crushers, grinders, shredders, and mills are essential machines in material processing, each designed for specific tasks from breaking large rocks to producing fine powders.

Choosing the right equipment based on input material and desired output ensures efficient production, quality, and consistency, making these machines vital in modern industries.